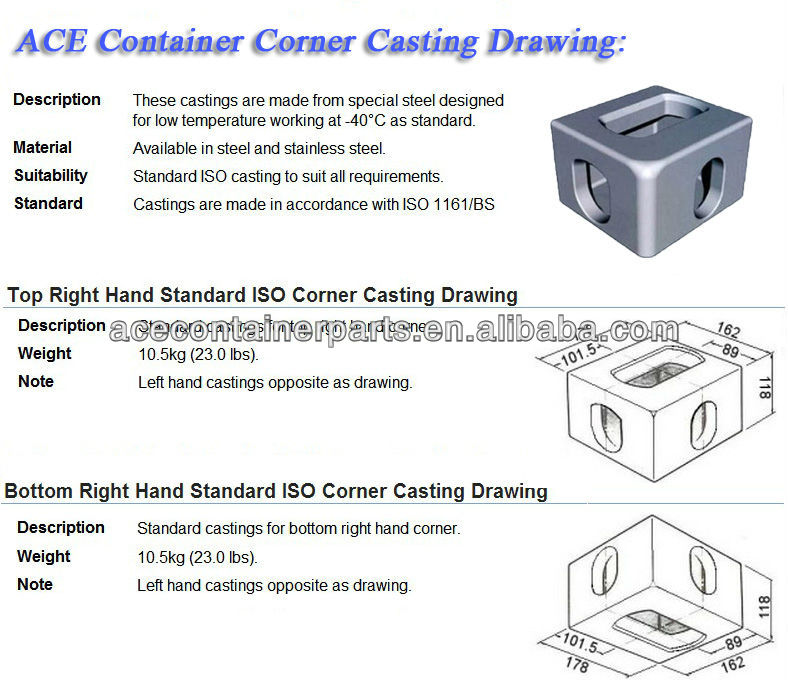

Iso Container Corner Castings For Shipping

Sold in sets of 8 container corner castings (or individually) Meets the ISO Standard (ISO 1161) for Container Corner Castings with Regard to Dimensions There are 2 each of 4 different marine shipping container corner castings per set: Bottom Left, Bottom Right and Top Left and Top Right.

A twistlock and corner casting together form a standardized rotating connector for securing shipping containers. The primary uses are for locking a container into place on a container ship, semi-trailer truck or railway container train, and for lifting of the containers by container cranes and sidelifters.

- Description ISO container corner castings/container fittings. OBM container parts manufacturer, specializing in the processing of international standard container corner castings, container side panels, container door locks, and hinges, etc., welcome to inquiry. A standard 20ft/ 40ft ISO container uses 8 corner castings consisting of.

- A twistlock and corner casting together form a standardized rotating connector for securing shipping containers. The primary uses are for locking a container into place on container ship, semi-trailer truck or railway container train; and for lifting of the containers by container cranes and sidelifters.

Description[edit]

The twistlock was developed in Spokane, Washington in the 1950s by transport engineer Keith Tantlinger.[1][2] The relative obscurity of this invention belies its importance to a more efficient world trade and transport, as the Tantlinger lock made handling and stacking standard containers much easier.

A major advantage of this approach to attachment is that containers, which may be stored or transported without being inspected for months at a time, do not require any maintenance in order to function effectively. Even with long term exposure to the weather the container remains as simple to move as ever. Only when corrosion is very extensive (to the extent of being easily visible) does the twistlock become dangerous to move the crate. The male part (which is more exposed and susceptible to damage) is placed on vehicles and equipment that are inspected very frequently, and will work with all standard containers.

Mechanism[edit]

The female part of the connector is the 7×7×41⁄2 in (180×180×110 mm) corner casting, which is fitted to the container itself, and has no moving parts, only an oval hole in the bottom. The hole is an oval 4.9 in (124.5 mm) on the long axis with two flat sides 2.5 in (63.5 mm) apart. The male component is the twistlock, which is fitted to cranes and transport bases. This can be inserted through the hole (it is roughly 4.1 in or 104.1 mm long and 2.2 in or 55.9 mm wide), and then the top portion (normally pointed to make insertion easier) is rotated 90° so that it cannot be withdrawn. The mechanism is similar to that of a Kensington lock, but on a much larger scale. The maximum size and position of the holes in the connector is defined in international standard ISO 1161:1984. The tensile strength of a twistlock is rated at either 20 or 25 tonnes.[3]

Some twistlocks have built-in levers or mechanisms, while simpler versions require tools for installation or removal. Some twistlocks are permanently installed (e.g. on the decks of container ships or on the beds of tractor trailers), while others are temporarily installed and removed as needed (e.g. to stack containers in storage yards).

Corner casting on a shipping container. The twistlock proper is inserted through a larger oval hole on the bottom.

Twistlock, unlocked position

Twistlock, locked position

Some twistlocks have a built-in lever

High-quality retractable twistlock

Close-up of twistlock on a rear corner of a container semi-trailer (Germany)

Rusty twistlock on a semi-trailer

Twistlocks on the deck of Majestic Maersk

Closeup of twistlock at Maritime Museum of Finland

Applications[edit]

Iso Shipping Container Corner Castings

Special types[further explanation needed] of twistlocks are also used in double-stack rail transport to secure the lower stack container with the upper one.

Twistlock engaged with shipping container at sea

Twistlocks on the base of a container ship. Foreground: unlocked; background: locked. The turnbuckles are 'lashing rods' used for additional stability

Containers can be joined vertically using these manually operated mid-locks.

These mid-locks are manually attached to the upper container, and then automatically lock to the lower container when stacked.

Twistlock attachment to a trailer (Japan)

Dockworker tosses a twistlock onto a shipping container

Dockworker installs a twistlock on a high stack of containers

Grounding of this container ship, the MV Rena off New Zealand on October 5, 2011, overstressed many twistlocks, resulting in a partial collapse of cargo stacks.

References[edit]

| Wikimedia Commons has media related to Twistlocks. |

- ^'The Lives They Lived'. The New York Times. 22 December 2011.

- ^Johna Till Johnson (September 29, 2011). 'The Engineer Who Transformed Shipping'. Wind Against Current.

- ^A Master's Guide to Container Securing, Lloyd's Register, London

- Peck and Hale (2000). 'Container Stowage and Securing Systems'(PDF). West Sayville, NY: Peck & Hale. Archived from the original(PDF) on 2011-07-15. Retrieved 2011-03-01.

- Levinson, Marc (2006). The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger. Princeton, N.J: Princeton University Press. ISBN0-691-12324-1.

- Nichols, C. Reid; Williams, Robert G. (November 2008). Encyclopedia of Marine Science. Infobase Publishing. p. 119. ISBN978-0-8160-5022-2. Retrieved 8 March 2011.

- SPTA-company (November 2008). SPTA.su. Infobase Publishing. p. 119. ISBN978-0-8160-5022-2. Retrieved 8 March 2011.